Product Information

Rubber Auxiliaries Trithiocyanuric Acid

Thiocyanic acid trimer is an inorganic compound with the chemical formula (CNS)3, also known as TMT, ammonium thiocyanate trimer and others.

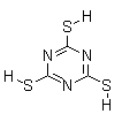

Product Name: Trithiocyanuric acid;1,3,5-Triazine-2,4,6-trithiol

Molecular Formula: C3H3N3S3 Molecular Weight: 177.26 CAS NO: 638-16-4 Structural Formula:

Product Properties:

1. Appearance: thiocyanic acid trimer is white crystalline powder.

2. Stability: stable at room temperature, but will decompose by heat.

3. Solubility: soluble in water, insoluble in organic solvents.

4. Chemical properties: trimeric thiocyanic acid has high oxidising properties and may cause fire when in contact with combustible materials.

Product Specification.

| Item | Specification

|

Appearance

| Indicator | Measured Value |

| Yellow Indeterminate Powder | Yellow Indeterminate Powder |

| Content(Assy),% | ≥95%(Ag Titration) | 96 |

| Melting Point(m,p) | ≥300℃

| 300℃

|

| Heating Loss%(w,c) | ≤0.50

| 0.4 |

| Ash% | ≤0.30

| 0.3 |

Product Property: yellow powder, insoluble in water, slightly soluble in methanol, acetone, dihexane, soluble in THF.

Preparation Method:

The preparation method of trimeric thiocyanic acid is relatively simple, usually through the solution of ammonium thiocyanate or thiocyanic acid for evaporation and crystallisation to get the pure product.

Poduct Uses: It is widely used as heat stabilizer for polypropylene, rubber and other polymers, vulcanising agent for ethyl chlorinated acrylate-ethylene polymer, acrylic rubber and other polymers, applicable to acrylate rubber ACM, chloroether rubber CO.ECO and neoprene rubber CR, also can be used for rubber-plastic blending materials. The product vulcanisation speed, coke safety, can shorten the vulcanisation time, no need for two-stage vulcanisation, made of vulcanised rubber with oil resistance, heat resistance to change pressure of the remarkable vulcanised rubber mechanical properties. It is special vulcanising agent for acrylate rubber. As a special vulcanising agent, it can also be used in chlorohydrin rubber and neoprene rubber, and can also be used as a co-curing cross-linking agent for butyl rubber and PVC, or as a cross-linking agent for PVC phenolic resin alone.

Product Usage: It is a special vulcanising agent for acrylate rubber, with fast vulcanisation speed and oil, heat and compression resistance of the vulcanised rubber. The dosage is generally about 1 part, with 2 parts of BZ (zinc dibutyl dithiocarbamate), a small amount of anti-coking agent CTP. The vulcanisation temperature is 160-170℃, the second stage vulcanisation is 170℃×3-4 hours. Package: 25kg plastic woven bag, paper-plastic bag, kraft paper bag.

Warranty period: one year sealed at room temperature

Company information

The company's main import and export products include

(1)Polymers:The advantage of Polymers is that they can be easily formed into the desired shape using a variety of techniques such as solution casting, melt moulding, or machining. As a result, polymer-based implants are relatively inexpensive to manufacture. Polymers can also react so that different chemical molecules can attach to the surface of the implant, making it more compatible with the body's surroundings.

(2)Organic Raw Materials:It has a wide range of uses, which can be divided into three aspects: first, it is used as a raw material for the production of polymer chemical products, i.e., monomers for polymerisation reactions; second, it is used as a raw material for other organic chemical industries, including fine chemical products; and third, it is used as a solvent, refrigerant, antifreeze, and gas adsorbent. Basic organic chemical industry is the basis for the development of the production of various organic chemical products, is the main component of the modern industrial structure.