Polyethylene is a thermoplastic resin made by Polymerization of ethylene, is one of the most common Plastics And Products, the annual production of more than 100 million tons of polyethylene resin, accounting for 34% of the total plastics market. Other common plastics and products include PET (Polyethylene Terephthalate).PVC (Polyvinyl Chloride).PP (Polypropylene) .PPS(Polyphenylene Sulfide)and so on.

PE is a typical crystalline polymer, the melting point of 130 ℃ ~ 145 ℃, which is characterized by tasteless, odorless, non-toxic, non-toxic, non-toxic, non-toxic surface, milky-white waxy particles.

High-pressure Polyethylene (LDPE), the full name of high-pressure low-density Polyethylene, commonly referred to as "high pressure" in the industry; low-pressure polyethylene (HDPE), full name low-pressure high-density polyethylene, referred to as "low pressure".

The difference between high pressure polyethylene and low pressure polyethylene: mainly from the production process and use to distinguish: High pressure: using polymerization grade ethylene as raw material, oxygen (or air) or organic peroxide as catalyst, in the tubular reactor tank reactor, using 130-280Mpa ultra high pressure and 300 degrees Celsius high temperature process for polymerization to make. Low pressure: high-purity ethylene as raw material, propylene or 1-butene as comonomer, alkane as solvent, in the presence of high activity catalyst, using a certain temperature (65-85) and pressure (0.1-0.7Mpa) The solution polymerization is carried out, followed by separation, drying, kneading, and granulation.

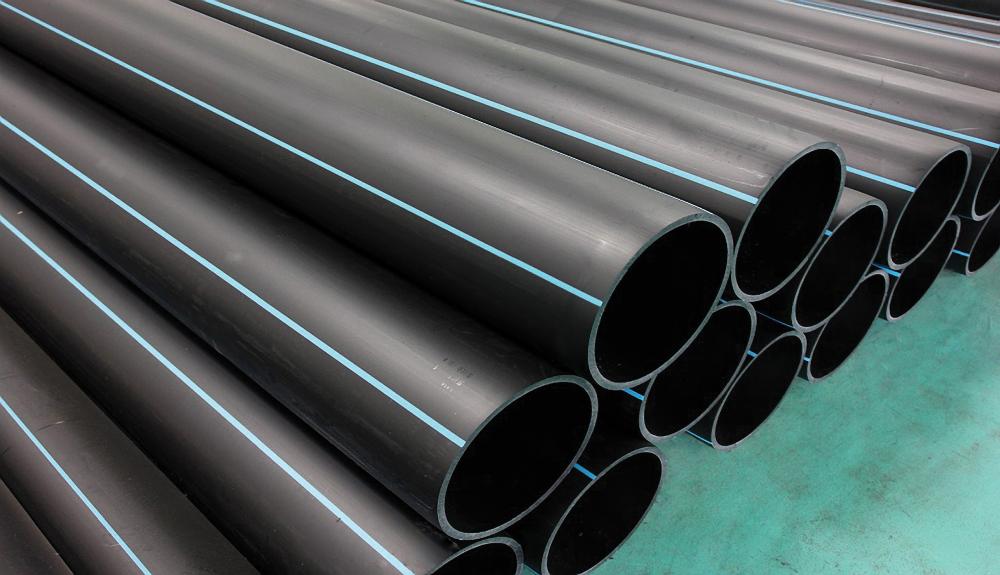

Uses: High-pressure polyethylene: suitable for processing methods such as extrusion, blow molding, injection, vacuum, molding, coating and rotary molding, manufacturing food security film, light packaging film for agricultural film industry, general transparent film, sheet, wire, cable protection Sets, tubes, chemical containers, synthetic paper, foamed products, etc. Low-pressure polyethylene: mainly used for blow molding, manufacturing various bottles, cans, barrels and containers for injection molding, manufacturing pots, baskets, baskets, totes and industrial machinery parts, for extrusion molding various pipes, Film, woven bag narrow wire, monofilament, etc.

Main Application: LDPE is mainly used in film applications, with good transparency and excellent processing properties, but poor mechanical properties. There are many applications for HDPE: drawing (that is, woven bag fiber), injection molding (various daily necessities), blown film (that is, film application), hollow (blow molding, such as some PE bottles.